TECNA, 6075 MFDC Series Press / Projection Welder (56kVA)

TECNA 56 kVA MFDC Press / Projection Welder – Model 6075 is designed to meet every need of spot welding. The frame of this line of machines has been designed by TECNA so to facilitate the operator’s work. The control unit, the pneumatic commands and the pressure gauge have been placed at the top so to enable the operator to use them smoothly. The inverter technology, which these machines are provided with, allows a higher welding quality, an extreme precision in time and current and a reduction in costs, installation ones included. The welding time is adjusted in milliseconds thus allowing the best set-up. The welding current is supplied continuously and constantly and is not affected by the dimensions of the welding circuit.

TECNA 56 kVA MFDC Press / Projection Welder – Model 6075 is designed to meet every need of spot welding. The frame of this line of machines has been designed by TECNA so to facilitate the operator’s work. The control unit, the pneumatic commands and the pressure gauge have been placed at the top so to enable the operator to use them smoothly. The inverter technology, which these machines are provided with, allows a higher welding quality, an extreme precision in time and current and a reduction in costs, installation ones included. The welding time is adjusted in milliseconds thus allowing the best set-up. The welding current is supplied continuously and constantly and is not affected by the dimensions of the welding circuit.

- Medium frequency welders, designed to obtain high quality welding.

- Modular design of mechanical structure, arms, brackets, cylinders.

- Cylinder with chrome plated stem for heavy duty works and long life; adjustable anti-rotation device.

- Lubrication free pneumatic components to eliminate oil mist and to protect the environment.

- Adjustable double-stroke cylinder with key control.

- Built-in compressed air filter unit. Compressed air disconnection device.

- Water-cooled transformer, plates, electrode-holders and electrodes; transformer with epoxy resin coated windings.

- Two stage electric foot control for clamping and welding pieces only if correctly positioned.

- Pre-setting for additional double stage electric foot switch connection for the direct recalling of a different welding program.

- Arranged for all models: two-hand safety control with timer and removable key selector, assuring the best safety. The two-hand control device is standard on projection models only (it is available upon request on spot welder models).

- Emergency push-button to stop the machine immediately.

* Features and specifications may vary, and are subject to change without notice

| SPECIFICATION | UNITS | WTP-6075 | WTP-6075A | WTP-6075 w/8031 | WTP-6075A w/8031 |

| Spot Welder | Spot | Spot | Spot | Spot | |

| Projection Welder | Projection | Projection | Projection | Projection | |

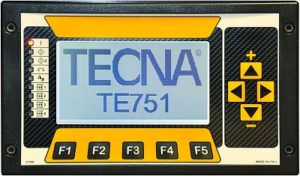

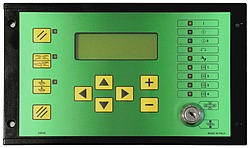

| Standard Control | TE751 | TE700 | TE751 | TE700 | |

| Power @ 50% Duty Cycle | kVA | 56 | 56 | 56 | 56 |

| Max Power | kVA | 200 | 200 | 200 | 200 |

| No-Load Secondary Voltage | V | 8.4 | 8.4 | 8.4 | 8.4 |

| Short Circuit Current | A | 25,000 | 25,000 | 25,000 | 25,000 |

| Thermal Current @ 100% | kA | 4.9 | 4.9 | 4.9 | 4.9 |

| Supply Voltage (3-Phase @60Hz)* | V | 440 | 440 | 440 | 440 |

| Delayed Fuses @ 440VAC | A | 50 | 50 | 50 | 50 |

| Primary Cables Ø (up to 30m) | mm² | 25 | 25 | 25 | 25 |

| Compressed Air Supply | psi (bar) | 94.3-145 (6.5-10) | 94.3-145 (6.5-10) | 94.3-145 (6.5-10) | 94.3-145 (6.5-10) |

| Air Consumption per 1000 Spots @ 94.3 PSI (650kP / 6.5 bar) | SCF (N/m³) | 307-92 (8.7-2.6) | 307-92 (8.7-2.6) | 307-92 (8.7-2.6) | 307-92 (8.7-2.6) |

| Throat Depth – To Electrode Holders | in (mm) | 15.7 (400) | 15.7 (400) | 19.7 (500) | 19.7 (500) |

| Throat Depth – To Tooling Platens | in (mm) | 11 (280) | 11 (280) | 15 (380) | 15 (380) |

| Max Electrode Force @ 94 psi (6.5 bar) | lbs. (daN) | 1034 (470) | 1034 (470) | 1034 (470) | 1034 (470) |

| Working Stroke | in (mm) | 0.2-3.2 (5-80) | 0.2-3.2 (5-80) | 0.2-3.2 (5-80) | 0.2-3.2 (5-80) |

| Adjustable Retraction Stroke (Standard) | in (mm) | 0.0-3.2 (0-80) | 0.0-3.2 (0-80) | 0.0-3.2 (0-80) | 0.0-3.2 (0-80) |

| Water Cooling @ 36 psi (250 kP / 2.5 bar) | gpm (lpm) | 1.6 (6) | 1.6 (6) | 1.6 (6) | 1.6 (6) |

| Min/Max Water Pressure | psi (bar) | 36-58 (2.5-4) | 36-58 (2.5-4) | 36-58 (2.5-4) | 36-58 (2.5-4) |

| Aerial Noise Produced | dB(A) | <70 | <70 | <70 | <70 |

| Measured Conditions | |||||

| Working Stroke | in (mm) | 1.9 (50) | 1.9 (50) | 1.9 (50) | 1.9 (50) |

| Welding Time | ms | 380 | 380 | 380 | 380 |

| Welding Current | kA | 18.8 | 18.8 | 18.8 | 18.8 |

| Working Rating (Welds per Minute) | #/min | 6 | 6 | 6 | 6 |

| Ø Arms | in (mm) | 2.4 (60) | 2.4 (60) | 2.4 (60) | 2.4 (60) |

| Ø Electrode Holders | in (mm) | 1.26 (32) | 1.26 (32) | 1.26 (32) | 1.26 (32) |

| Electrode Taper Size | 5RW/2MT | 5RW/2MT | 5RW/2MT | 5RW/2MT | |

| Tooling Platen T-Slot Spacing | |||||

| T-Slot Spacing | in (mm) | 1.77 (45) | 1.77 (45) | 1.77 (45) | 1.77 (45) |

| Bolt Size | in (mm) | 0.315 (8) | 0.315 (8) | 0.315 (8) | 0.315 (8) |

| Net Weight | lbs (kg) | 616 (280) | 616 (280) | 649 (295) | 649 (295) |

| Dimensions LxWxH | in | 44.1 x 16.5 x 73.4 | 44.1 x 16.5 x 73.4 | 52.0 x 16.5 x 73.4 | 52.0 x 16.5 x 73.4 |

| (mm) | (1120 x 420 x 1838) | (1120 x 420 x 1838) | (1320 x 420 x 1838) | (1320 x 420 x 1838) | |

| *May be supplied capable of operating on other voltages/frequencies. Please ask for details. | |||||

| Item 6073 |

Item 6074 |

Item 6075 |

Item 6073A |

Item 6074A |

Item 6075A |

Photo |

Description |

| |

|

Adjustable double stroke. | |||||

| |

|

|

Item 8030 Valve to stop the flow of the water cooling when the machine is off and flow switch which makes the welder stop if the cooling water does not circulate. |

||||

| |

Item 8031 Longer arms length for item 6075 (L=500 D=380). |

||||||

|

Item 8033 Double stroke control device with pneumatic foot instead of key one. To be used only for spot welding when the work necessarily requires it. |

||||||

|

Item 8037 Proportional valve. Allows to adjust the working pressure directly from the control unit and to combine a proper pressure value to each program. Assures constant and accurate working pressure. It can be used only on welders equipped with TE700 control unit. |

||||||

|

Item 8038 Position sensor. It can be used only on welders equipped with TE700 control unit. |

||||||

|

Item 8042 Rotary selector for recalling the welding programs. It can be used only on welders equipped with TE700 control unit. |

||||||

|

Item 8043 Electrodes descent without pressure for both maintenance and set-up |

||||||

| |

|

Item 73070 Additional double stage electric foot switch for the direct recalling of a different welding program. L=1.4 m. |

|||||

|

Item 73038 Additional double stage electric foot switch for the direct recalling of a different welding program. L=2.4 m. |

||||||

| |

|

|

|

|

|

|

Item 50214 Serial interface RS232, enabling the connection with a serial printer or a personal computer for production data recording. |

|

Item 6033 USB interface board. |

||||||

| |

|

|

Item 72628 Two-hand safety control on pedestal, adjustable height. Recomended for the operator safety according to the working requirements. |

![]() =Standard

=Standard ![]() =Upon request

=Upon request

Feature |

TE751

|

TE700

|

| Ammeter | ||

| Parameters No. | 16 | 26 |

| Programs No. | 150 | 250 |

| Welding programs recallable from foot pedal | 2 | 2 |

| RS232 Interface | ||

| USB Interface | ||

| Constant current | ||

| Stepper function | ||

| Constant energy | ||

| Two-hands input | ||

| Higher and lower current limits |

![]() =Standard

=Standard ![]() =Upon request

=Upon request